The Problem:

A very large iron ore operation in Australia with multiple AG mill grinding and processing trains required better estimation of operating costs for improved mining planning and scheduling.

The issue at many operations remains that operating cost, of which the grinding circuit typically makes up about 50%, is not captured accurately or even considered in mine optimisation. The estimation of grinding specific energy (kWh/t), denoted SE, when added as a field to the geological block model allows mine planners to schedule more ore to the plant and select ore requiring lower energy intensity for breakage, thereby lowering operating costs and increasing profitability.

It is important to note that NPV and other financial parameters can also be derived from SE, according to:

- Throughput (tph) = SE divide by installed grinding power

- Plant OpEx ($/t) = SE x throughput x energy cost

- NPV using revenue and plant OpEx estimates

The alternative is that all the blocks in the geological block model are assigned one throughput value or operating cost. A worse yet common scenario is mine planning based on head grade only.

The Solution:

At this very large operation with significant stockpiling, PETRA implemented MAXTAGeomet ore tracking to generate a data set which is a replica, or digital twin, of the mining operation from the block model to AG mill processing using operating data. The digital twin of the operation formed the basis of machine learning models to predict SE. The input to these models consisted only of parameters in the block model.

The result was a machine learning SE prediction model from which estimates for SE for each block can be populated into the geological block model for more informed mine planning and scheduling using financial parameters.

The SE machine learning model accuracy is shown below, it is a plot of actual versus predicted and includes accuracy metrics such as error and correlation.

PETRA worked closely with site geologists and mine planners to assess data trends including input correlations and to ensure stockpile characteristics and ore delivery to the mills was sufficiently understood and captured in the modelling.

The Results:

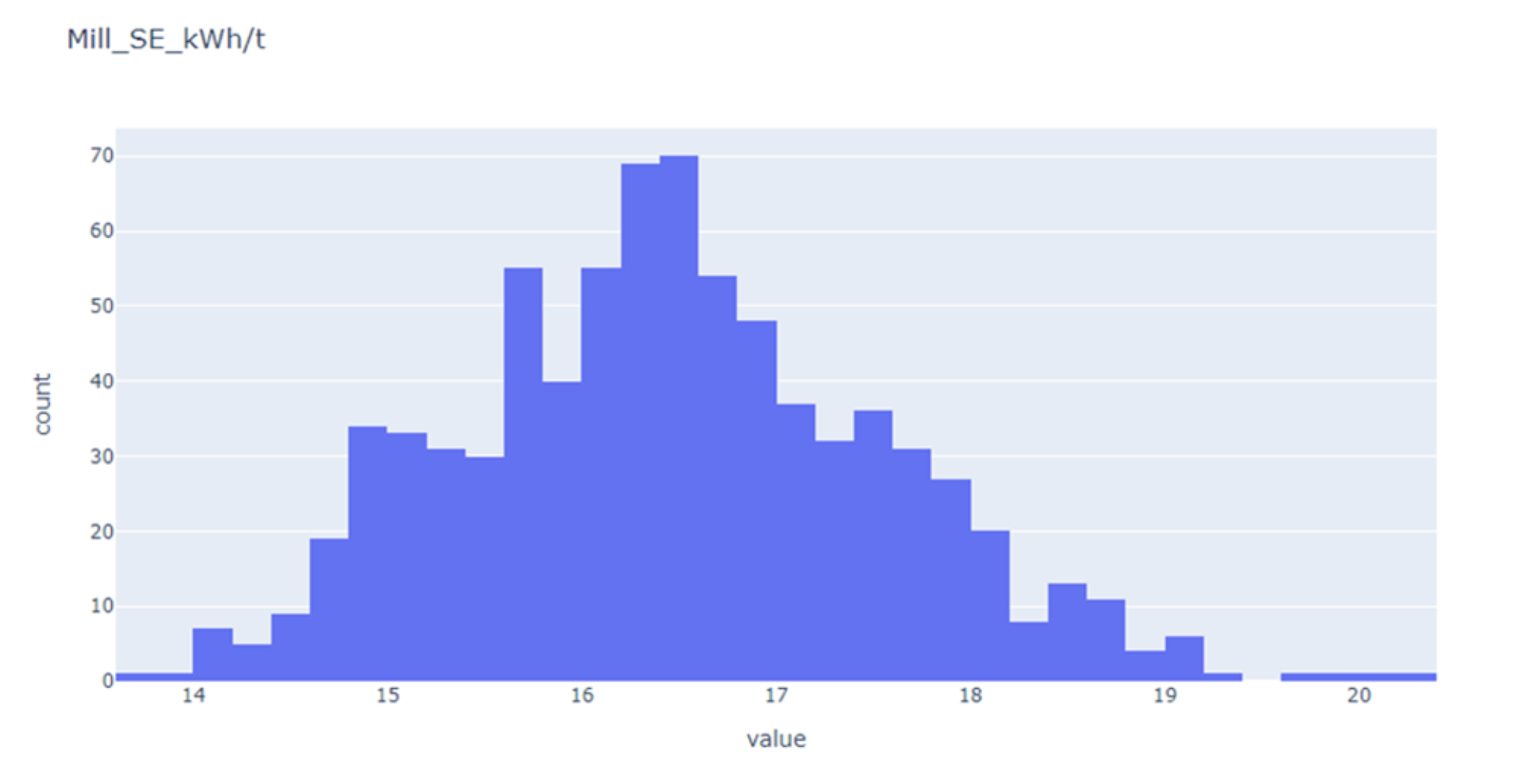

SE was derived according to AG mill, ball mill and pebble crusher power draw, all divided by the feed rate (plant throughput), resulting in SE (KWh/t).

The results of the data exploration and model implementation showed the range of SE between 14-20KWh/t over the training period, this is a variation of about +/-20% on the mean SE of 16.5kWh/t. Typically, energy efficiency gains of 10% or greater are deemed feasible and impactful in operations.

The inclusion of SE in the geological block model and the related financial measures that can be derived from SE dramatically expands the mine optimisation capabilities and can better inform business profitability. It is a significantly improved approach to the common mine planning to head grade.

MAXTA is available now for demonstration, please contact us to arrange a walk through.