We’re very excited to launch our new MAXTA Portal!

PETRA has seen the scale of pit-to-port and mine-to-mill optimisation software applications grow rapidly over the past year. In response to the need for larger, more complex mining value chain optimisation PETRA recently released a new version of MAXTA and it’s suite of applications at a launch event in Perth, WA.

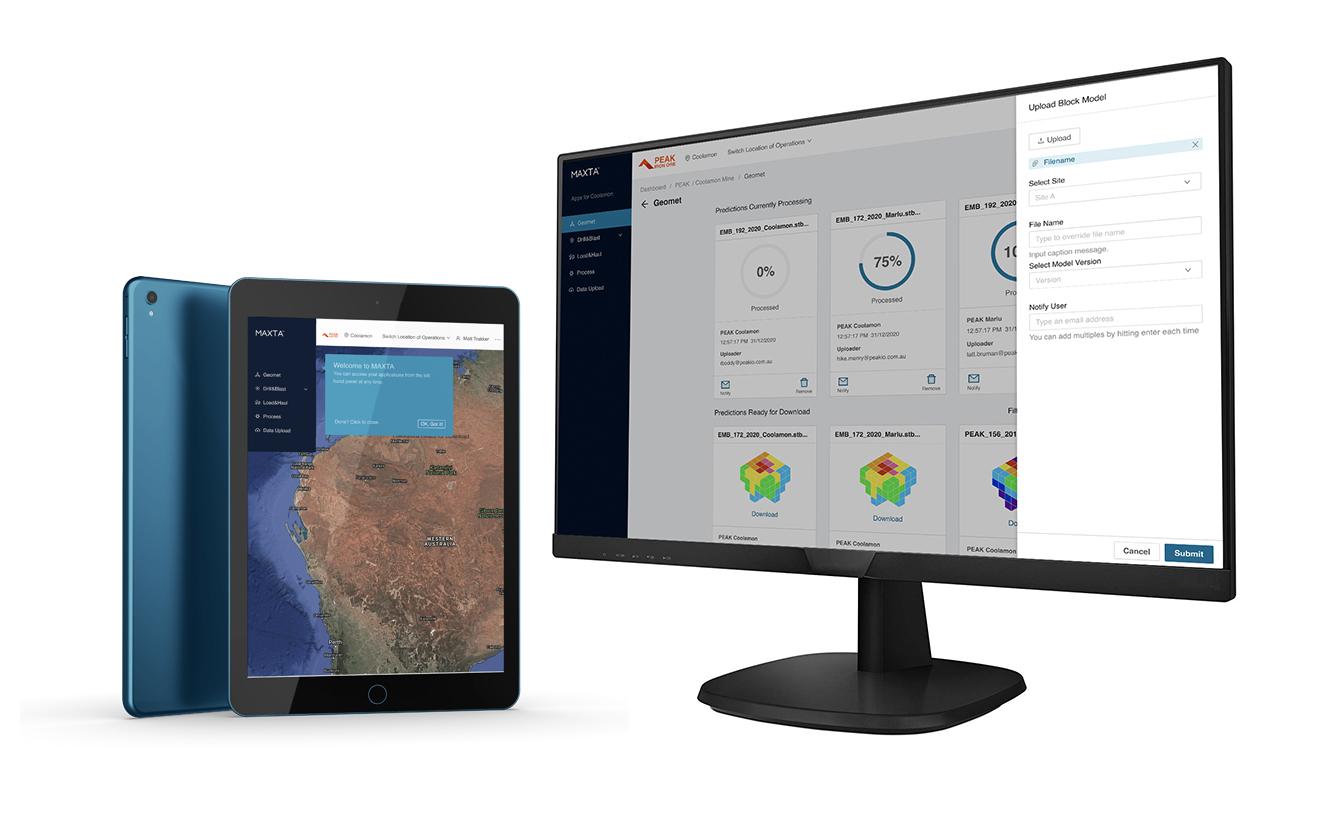

This new version of MAXTA allows for scalability across multiple mining operations by giving global access to a suite of mine-to-mill and pit-to-port applications along the entire value chain.

By virtually re-mining the orebody, machine learning models accessible through MAXTA provide high accuracy inputs to mine planning (e.g. dig rates, crusher downtime, mill throughputs and plant recovery), whilst the mathematical optimisation layer shows drill and blast engineers and metallurgists which design and setpoints provide the best performance for the specific ore being blasted, or processed.

A major challenge with mine-to-mill and pit-to-port in mining in the past has been sustaining the value generation beyond six months to a year. MAXTA is a packaged, supported and contextualised solution for mine-to-mill and pit-to-port value chain optimisation which aims to generate and sustain that value long beyond the average periods.

The applications available within MAXTA are designed to support operations by working seamlessly with existing day-to-day workflows and interoperates with widely used mine planning and processing applications. PETRA was the first company to deliver a software solution addressing this challenge, with MAXTA now delivering huge value to mining companies and being used every day by engineers on site.

“MAXTA is the first enterprise scalable platform for the delivery of advanced machine learning and AI benefits into a range of specific high value stages of mining and processing. Designed with the engineer in mind, it’s modern human-centric user interface is fluid and intuitive.”

Unlike individual and custom software deployments, MAXTA is a streamlined and efficient experience which can be easily applied across very large, very complex operations. Applications within MAXTA are capable of fast, accurate predictions, block by block, for an entire orebody and how the downstream value chain processes will behave for various geologies. MAXTA offers one interface for all users across the value chain to target specific areas or processes, even across multiple sites.

PETRA was very pleased to be able to join with customers and partners in Perth to celebrate this launch and demonstrate the new capabilities.

The MAXTA launch also sees the user interface for MAXTAGeomet and MAXTADrill&Blast updated to provide more visualisation and interaction with data, and all MAXTA applications within the suite are now feature interoperability with Maptek’s Vulcan mine planning software to facilitate easy and accurate use of MAXTA results in day to day planning, design and decision making.

Working closely with our largest customers has driven this development and PETRA is very excited about the ability to deliver scalable, supported packaged software solutions.

MAXTA has already been proven to create immense value across multiple stages of a mining operation and now that value can be targeted at a site, operation or enterprise scale.

MAXTA is available now for demonstration, please contact us to arrange a walk through.