We’re delighted to announce that our PRODFINDER® data integration solution is a finalist in 2016 Mining Magazine Awards!

Mining Magazine 2016 Final Nominees

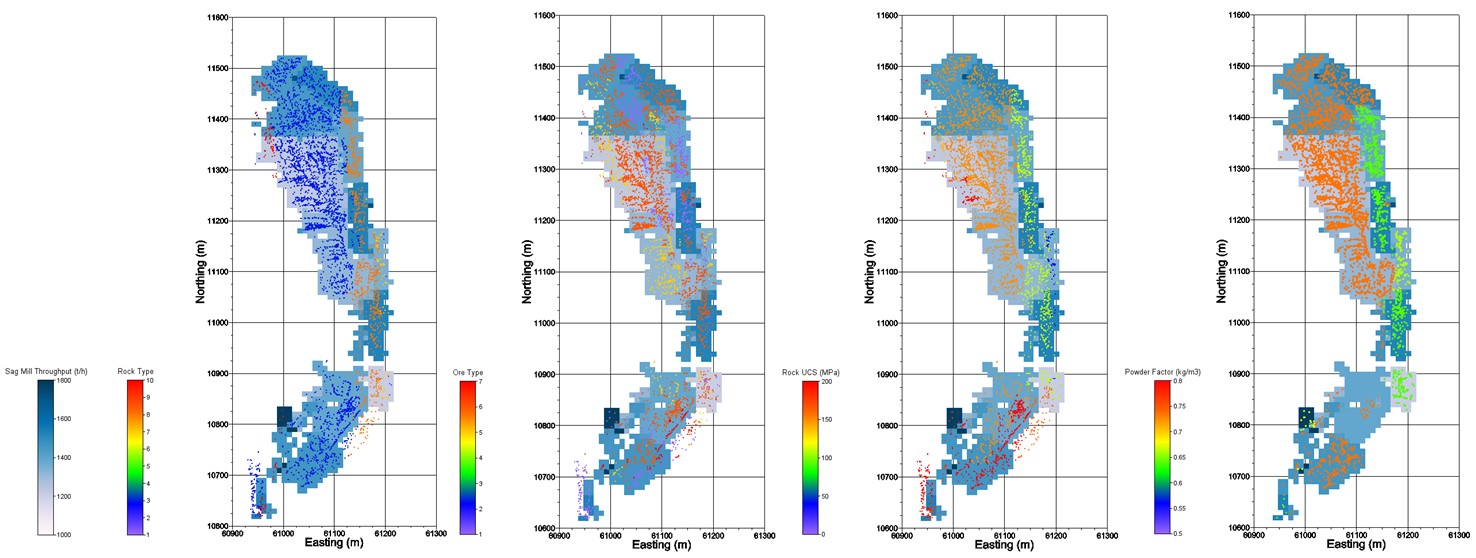

PRODFINDER® algorithms automatically link 3D geological, dispatch and blast data to processing plant historical data, and simultaneously take into account geology, blast design and plant operating factors to reveal optimal blast designs. Virtual stockpiles track ore from the pit to the plant to predict plant performance measures for different stockpile blends. PRODFINDER® makes it possible to conduct low-cost mine to mill type projects without site trials and has been nominated in the drill and blast category.

In addition to the data integration visualisations shown; geology, blast design, hydrogeology, weather, and fragmentation are all analysed simultaneously. These factors can be used to predict plant performance and optimise blended stockpile composition. It can be used for small focused projects, or big data mine to mill projects.

PRODFINDER data integration and big data analysis can be applied to any mining operation, whether that be; open pit, underground, coal or hard rock. Check out our PRODFINDER case studies here:

Over the past two years we have developed PRODFINDER from a big data mine to mill study methodology in to the world’s first digital twin for value chain optimisation. Our digital twin, MAXTATM is a platform agnostic application, and can be deployed as a platform agnostic link between the mine and the processing plant.

Contact us to find out how PRODFINDER and MAXTATM can be used to integrate data assets.